I-CPL-Coil ukuya kwi-Coil polishing Line

I-CPL-Coil ukuya kwi-Coil polishing Line

Intshayelelo yeMveliso

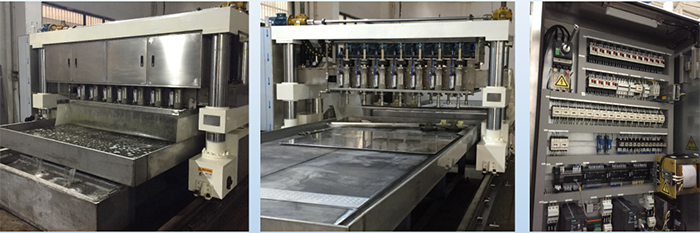

I-Coil ukuya kwi-Coil Grinding Machine (Uhlobo olumanzi) isebenzisa i-Oli yokuSila okanye i-Emulsion njengeMedia ukuphumeza umphumo ococekileyo kunye nobengezelelekileyo wokusila kwiikhoyili zensimbi ezingenasici ezibandayo kwaye zinokususa iziphene kwi-Stainless Steel Surface.Umtshini wenzelwe ukufumana i-Finishing No.3 (i-Coarse Finishing, i-Abrasive Grain esuka kwi-G60 ukuya kwi-G150) okanye i-No.4 (i-Fine Finishing, i-Edume kakhulu, i-grasive grain abrasive evela kwi-G180 Okanye ngasentla) kunye ne-HL Finishing (i-Hairline Finishing, i-Chacterified by Smooth and umgca omde).

I-Coil kwi-Coil Grinding Machine (Uhlobo olumanzi) ikwafanelekile kunyango lomphezulu we-CRM iipleyiti emva kokukhetha kwi-Mill;isusa iziphene ezincinci kwaye iphucula umgangatho weemveliso ezinokukhubazeka ukuya kwi-Qualified Material.

I-Coil kwi-Coil Grinding Machine (Uhlobo olumanzi) lunokuqhuba i-coil ye-Stainless Steel ngobuninzi kunye nengqolowa engaguqukiyo, Isetyenziswa ngokubanzi kwiimarike eziphezulu ezifana noMhlobiso, i-Elevator, i-Appliance yeKhaya njl.

I-Coil Standard kwi-Coil Type Grinding Machine (Uhlobo olumanzi) luqulunqwe ngokukodwa kwi-De-Coiling and Re-Coiling System, i-2 Heads Bottom Grinder, i-4 Heads Top Grinder kunye ne-4 Head HL Grinder.

I-Sander ephantsi isetyenziselwa ukususa uxinzelelo lwangaphakathi lwe-Coil, ukuqinisekisa ukuba ikhoyili ayiyi kukhubazeka emva kokusika.

I-4 Heads Top Grinder kukuqinisekisa iinkozo ezingaguqukiyo ukusuka kwintloko yekhoyili ukuya kumsila wekhoyili kunye nokuqinisekisa ukuguquguquka kwiikhoyili zokusila zobubanzi obahlukeneyo.

I-HL Grinder inokuhlangabezana nemfuneko ephezulu kumthengi ngeeNkozo ezicacileyo nezingaguqukiyo.

Ubuninzi beeNtloko zokuSila bunokuthi buxhomekeke kwimfuno yomthengi (IE Inokuthi ibe yi-1 ye-Bottom Grinder, + 2 Top Grinders Etc.), okanye enye i-SB Grinder inokongezwa ekugqibeleni.

Umsebenzi onzima owakhiwe, i-Coil ukuya kwi-Coil yokuSila umatshini (Uhlobo olumanzi) ibonakaliswe ngu:

--- INkqubo yokuRecycling eyakhiwe ngokugqibeleleyo, Akukho ngcoliseko lokusingqongileyo -INkqubo yokuRecycling

idibanisa iRough Mesh Filtration kunye neFine Paper Filtration, ngaloo ndlela ukuSila inkonkxa yolwelo

zihlaziywe kakuhle kwaye ziphinde zisetyenziswe.

---Ukulandelela ibhanti okuzenzekelayo kunye nokunyanzeliswa kwebhanti ye-hydraulic / pneumatic iqinisekisa i-Optimum

Ukungqinelana kunye nokunciphisa iindleko zokusebenza.

--- Izicwangciso zophumezo ezicwangcisiweyo kwangaphambili zenxalenye yobunzima, intloko yebhanti ye-abrasive Ubunzulu

kunye nebrashi yentloko ubunzulu

--- Ulungelelwaniso lokutyeba oluzenzekelayo, kunye neDigital Read-Out

--- Isakhelo somatshini owomeleleyo, ukungcangcazela kutsalwe kakuhle

--- IRoller enkulu yoQhagamshelwano ene-Perfect Static kunye neDynamic Balance, iHigh Spinning

Kwaye ubomi obude beebhanti ze-Abrasive buqinisekisiwe

--- Ukusebenza okuphezulu, kunye nokuSetyenziswa kwamandla aphantsi-30% Amandla anokugcinwa kunezinye

umatshini.

--- Utshintsho olukhawulezayo lweeBhanti eziAbrasive

--- Eyona Ndleko Yokusebenza

Ukucoca kunye nenkqubo yokomisa:

--- Uyilo oluDityanisiweyo, aMalungu aPhambili onke enziwe ngeNtsimbi eNgatyiwayo, iLife Span inokuba ngaphezulu

ngaphezu kwe-20 Years Plus.

--- I-Recycling Water Tank, i-Special Design, i-30% yamanzi inokugcinwa

--- Ukufudumeza okuzenzekelayo kunye neNkqubo yokuGcina ubushushu, i-70% Amandla anokugcinwa.

--- Isivuthelo saMandla esiPhezulu sokuqinisekisa ukuba akukho phawu lwamanzi emva Kokomiswa.

--- I-Lamination Direct emva kokumisa, ukuTension kweFilimu kunye ne-Braking System, ukusika iFilimu ye-Auto

ngobuchule obuphezulu.Ifilimu yeBubble Free.

Ukuhanjiswa komgca kunye ne-De-Coiler kunye ne-Re-Coiler Control system yokulawula uxinzelelo

--- UThutho lwe-Servo Motor: Ulawulo lwe-AC, i-30% yoGcina amandla

--- I-De-Coiler kunye ne-Re-Coiler inokuvula nokuba kuPhantsi okanye Phezulu, Isebenzela iCoil ukusuka

nasiphi na isisila emhlabeni.

--- I-Re-Coiler Tension Unit luyilo lwethu oluKhethekileyo, uzinzo luphuculwe kakhulu.

Inzuzo yeZS CPL

1. Umboneleli wesisombululo, i-ZS inikeza umgca opheleleyo oquka i-Unwinder, i-Rewinder, i-Loading Car, i-Pinch Roll, i-Flattener, i-Crop Shear, i-Washing and Drying system, i-PVC coater.Kwangaxeshanye sibonelela ngeSixokelelwano sokuCwangcisa okuPholisayo kunye neNkqubo yokuRisayikilishwa, uMqokeleli weNkungu, iNkqubo yokuLwa noMlilo kunye noMtshini wokuFaka iBriquetting.2. Akukho ziphene kunye namanqaku okuxoxa ukusuka kumgca 3. Isantya somgca ukuya kwi-40m / min max.

4. Umgca ufanelekile kwiiyure ezingama-24 kwimveliso eqhubekayo

5. Inqanaba eliphezulu le-Automation, okt Load Constant.Inkqubo yokulandelela i-Welding Seam (ubonelelo ngokuzikhethela kunye ne-welder)

6. Ukusebenza kunye nokugcinwa kobuhlobo

| Uhlobo lwezinto: | Iikhoyili zensimbi ezingenasici | |

| Amandla okuqina obuninzi: | N/ mm2 | -850 |

| Ubuncinci / Ubuninzi bezinto eziphathekayo: | mm | 0.4 - 3 |

| Ububanzi bomtya ubuncinci/ubukhulu: | mm | 600 - 1600 |

| Ubunzima bekhoyili enkulu ekungeneni: | t | 30 |

| Ikhoyili yokungena idayamitha yangaphandle min/max: | mm | 1000 - 2100 |

| Ikhoyili yokungena idayamitha yangaphakathi: | mm | 508/610 |

| Ubunzima bekhoyili enkulu ekuphumeni: | t | 30 |

| Phuma kwidamitha yekhoyili ubuncinci/ubuninzi: | mm | 1000 - 2100 |

| Phuma kwidayimitha yangaphakathi yekhoyili: | mm | 508/610 |

| Isantya somgca: | m/umz. | Max.I-40 yokubuyisela umva.5-35m/min ukusetyenzwa |

I-CPL isetyenziselwa ukukhutshwa kweziphene ezincinci kwi-coil ebandayo ye-SS kwi-wet, ifumane ukugqitywa kokuhlobisa, okt No.3, No.4, HL, SB & Duplo.Ukupholisa kunokuba yi-emulsion okanye i-oyile yeminerali.Ukuhluzwa okupholileyo kunye nenkqubo yokuhlaziya ibalulekile kumgca opheleleyo.I-ZS CPL yenzelwe ukuqengqeleka kwekhoyili ebandayo ukuya kwi-coil processing ukusuka kwi-100 ukuya kwi-1600 mm ububanzi kunye nobukhulu obuphakathi kwe-0.4 ukuya kwi-3.0 mm.I-WUXI ZS ikwabonelela nge-CPL eyomileyo.Ibhanti ye-Cork iya kusetyenziswa ukufumana ukugqiba okufana ne-Scotch-Brite finishing (SB), isantya sokutya se-CPL esomileyo sinokuba yi-50m / min okanye ngaphezulu.

Isicelo:

Izicelo eziqhelekileyo ze-NO.4 & HL ziquka: I-Escalator, i-Escalator, i-cladding yangaphakathi, i-facades yokwakha, i-Appliance yaseKhaya, njl.

Unyango olongezelelweyo luhlala lwenziwa kwi-No.4 kunye ne-HL surface: Umbala we-PVD, i-Pattern eqoshiwe, i-Anti-Finger Print Processing, Ukubiza ezimbalwa, ziqhelekileyo.

Intshayelelo yeNkampani

Imbali yethu:

Ingcaphephe yeFlat Surface Abrasives Belt Grinding of Metal: Le thagethi isikhokelela ekugcineni uphando kwintsimbi yokusila kunye nokupholisha ngentsimi yeebrasives ezigqunyiweyo ukusuka kwi-1990s.

Ngo-2005 saqalisa ukuyila, ukuvelisa kunye nokudibanisa ii-abrasives ezibanzi zoomatshini bokusila bentsimbi.Ngokwanda okuqhubekayo kweshishini kunye nokutshintsha kwesakhiwo sabaninizabelo,

ngo 2015 WUXI Zhongshuo Precision Machinery Co., Ltd yasekwa.

Inkampani yethu:

Singabanini benkampani elawulwa phakathi.Inkampani ikwisiXeko saseWuxi, kwiPhondo laseJiangsu.I-capital ebhalisiweyo yi-8 yezigidi zee-RMB.Indawo yokwakha idlula i-7000 m2.Inani elipheleleyo labasebenzi li-52, kubandakanywa injineli yezinga loPhando lwe-1, iinjineli eziphezulu ze-2 kunye neenjineli ze-5.Sinoyilo lobungcali, ukuvelisa, ukudibanisa, ukufakela, ukugunyazisa kunye neqela lenkonzo yokuthengisa.

Iimveliso zethu

Sivelisa umatshini obanzi wokusila kunye nomatshini wokupolisha, umatshini wokuxubha, umatshini wokugqiba isibuko, umatshini wokugqiba ukungcangcazela, umatshini wokufaka i-embossing ye-coil yensimbi kunye neshiti, kubandakanywa ukungena kunye nokuphuma kwecandelo le-CGL (I-Coil ukuya kwi-Coil yokuLungisa umgca wokuSila kwi-Steel Maker) kunye ne-CPL (I-Coil ukuya kwi-Coil Polishing Line yeZiko leNkonzo), oko kukuthi i-Unwinder, i-Rewinder, i-Laading Car, i-Pinch Roll, i-Flattener, i-Crop Shear, i-Coolant Filtration kunye ne-Recycling inkqubo, inkqubo yokuhlamba kunye neyokomisa, i-Mist Collector, inkqubo yokuCima uMlilo.Sikwabonelela ngesixhobo sokuLayisha kunye neQela leeKomityi zeVacuum yeShiti ukuya kwiLin yokuSila

Abaxhasi bethu:

Uluhlu lwethu lwereferensi kubandakanya iTisco Daming, iWuxi Puxin, iZhejiang Bohai kunye nabanye abathengi abaziwayo baseTshayina.Sithumele iimveliso zethu kwilizwe laseYurophu njenge-Itali, iTurkey kunye neSatifikethi seCE.Sikwabonelela ngegrinder yokulinganisa ibhanti kumenzi waseTshayina obonelela ngezixhobo kwiNqwelomoya kunye neNyukliya ngaphakathi.

Izatifikethi zethu

Iiprojekthi

Ukudala ixabiso kumthengi kukufuna kwethu rhoqo.Ukwaneliseka kwakho ngamandla okuqamba kwethu okuqhubekayo.

I-CPL-Coil ukuya kwi-Coil polishing Line ye-Stainless Steel Service Centre

UMTHENGI:ILogo Simahla Akukho mlinganiselo Ipapashwe ngu-浦新金属

I-CPL isetyenziselwa ukukhutshwa kweziphene ezincinci kwi-coil ebandayo ye-SS kwi-wet, ifumane ukugqitywa kokuhlobisa, okt No.3, No.4, HL, SB & Duplo.Ukupholisa kunokuba yi-emulsion okanye i-oyile yeminerali.Ukuhluzwa okupholileyo kunye nenkqubo yokuhlaziya ibalulekile kumgca opheleleyo.I-ZS CPL yenzelwe ukuqengqeleka kwekhoyili ebandayo ukuya kwi-coil processing ukusuka kwi-100 ukuya kwi-1600 mm ububanzi kunye nobukhulu obuphakathi kwe-0.4 ukuya kwi-3.0 mm.I-WUXI ZS ikwabonelela nge-CPL eyomileyo.Ibhanti ye-Cork iya kusetyenziswa ukufumana ukugqiba okufana ne-Scotch-Brite finishing (SB), isantya sokutya se-CPL esomileyo sinokuba yi-50m / min okanye ngaphezulu.

Iphepha le-SPL ukuya kumgca wokubengezela kwiPhepha (Uhlobo olumanzi)

UMTHENGI:太钢大明

Ishiti ukuya kuMatshini wokuSila (Uhlobo olumanzi) lusebenzisa i-Oli yokuSila okanye i-Emulsion njengeMedia ukufezekisa umphumo ococekileyo kunye nobengezelelekileyo wokusila kwiishiti zetsimbi ezishushu okanye ezibandayo okanye iikhoyili.Umtshini wenzelwe ukufumana i-Finishing No.3 (i-Coarse Finishing, i-Abrasive Grain esuka kwi-G60 ukuya kwi-G150) okanye i-No.4 (i-Fine Finishing, i-Edume kakhulu, i-grasive grain abrasive evela kwi-G180 Okanye ngasentla) kunye ne-HL Finishing (i-Hairline Finishing, i-Chacterified by Smooth and umgca omde).ZSSI-PL yenzelwe ukubandaishidi ukuya kwiphepha lokusilaukusetyenzwa phezulu ukusuka600 ukuya2200 mm ububanzi kunye nobukhulu phakathi kwe-0.4 ukuya kwi-3.0 mm.

I-PGL-Ukuguqa Umgca Wokugudisa kwi-Heavy Plate

UMTHENGI:西部金属

UkuSila okuZenzekileyo kunye noLayini wokuPholisha usetyenziswa ikakhulu ekususeni iziphene ekuqengqelekeni okushushu, ukucolwa kunye nenkqubo yokucoca kunye nesikali esishiyekileyo, kunye nokufezekisa ukutyeba okuceliweyo kunye noburhabaxa.Ukupholisa kunokuba yi-emulsion okanye i-oyile yeminerali.Ukuhluzwa okupholileyo kunye nenkqubo yokuhlaziya ibalulekile kumgca opheleleyo.ZSPGLyenzelwe ukusetyenzwa kwepleyiti enzima eqengqelekayo ukusuka kuma-600 ukuya kuma-2200 mm ububanzi kunye nobukhulu obuphakathi kwe-1.0 ukuya kwi-30 mm.I-WUXI ZS ikwabonelela nge-PGL eyomileyo.

UkuQeda isibuko (8K) Umatshini wePleyiti yeNsimbi eStainless

UMTHENGI:新华医疗

I-Advanteji yeWUXI 25 yeMirror yokuFinishing Machine yeStainless Steel Coil kunye neSheet.Iintloko ezigudileyo zeqela ngalinye zinokuzimeleyo okanye ngokudibeneyo liinyuswe phezulu naphantsi .Iziko refii-ling yekhompawundi yokugulisa ukunqanda umphezulu ongaphantsi kwediskhi yokugudisa fumana burnt.Intsimbi engenasici.Anti corrosion kwaye elideubomi.Intshukumo egudileyo ebuyelanayo ngesikhokelo somgca.

Isibuko sokugqiba umatshini weCold Rolling Coil kunye neSheet

UMTHENGI:MINOX(INDIA)

Uhlobo lwe-Pinch roll.Isebenzisa i-resin eboshiweyo ivili lokusila, i-disc Scotch-Brite, ikhompawundi yokupolisha equka i-5% Al2O3 + 5% ye-nitric acid + 90% yamanzi ukuphucula uburhabaxa bomphezulu inyathelo ngenyathelo, ekugqibeleni ukugqitywa kwesipili esiphezulu kunokufumaneka (8K).

Ukulayishwa ngokuzenzekela/Ukukhuphela isiXhobo ngeQela leVacuum Cup

UMTHENGI:博海金属

Iqukethe isakhelo se-gantry esenziwe nge-welded, i-carbon steel kunye nomlinganiselo ofanelekileyo wokuxhasa uxinzelelo lokusebenza.Esi sixhobo sinala maqela alandelayo: Iyunithi yoguqulo, iyunithi yokunyusa, iyunithi yokucofa ivacuum.

Iyunithi yokuguqulela ikhokelwa ngumkhombandlela we-liner, eqhutywa yi-servo motor nge-gear kunye ne-pinion.Iyunithi yokuphakamisa ekhokelwa yi-liner guide, eqhutywe yi-piston ye-pneumatic.Iyunithi yokuchola yenziwe ngezibambi ezi-3 ezilungelelanisiweyo ezineekomityi zokufunxa ezili-18, ibha ikwindawo esisigxina kodwa ikomityi nganye yokufunxa ingakwazi ukuhamba ngobude, umqhubi unokukhulula umzobo, alungise indawo yekomityi yokufunxa, atshixe kwakhona. ukulungiswa ngokulula.

Ikomityi nganye yokufunxa idityaniswe kwimibhobho yomoya ngamnye ukuze kuqinisekiswe ukusebenza kakuhle kwenkqubo, ikomityi nganye yokufunxa iqhagamshelwe kwi-spring arbor ukuqinisekisa indawo eyaneleyo yokubhobhoza phakathi kweekomityi kunye neqhekeza lomsebenzi.

ILaminator ezenzekelayo yoKhuseleko lweFilimu (umatshini wokugquma wePVC)

UMSEBENZI: UMBALA WESENTE (ITALY)

ILaminator ezenzekelayo / iPVC yoKutyabeka ngomatshini isetyenziswa ikakhulu kwiFilimu yokuLamination kuMphezulu wePhepha.Inokuthi yenzelwe icala kabini umaleko Laminating.

UkuLamination okuzenzekelayo, Ukusika okuzenzekelayo.

* IMode yoMshini: 400-2500 Uhlobo

* Ububanzi obuSebenzayo: 400-2500MM

* Isantya sokuSebenza: Isantya esisisigxina / isantya esinokulungiswa

* Isicelo: Lo matshini usetyenziswa ikakhulu kwiCoiler/De-coiler System,

Umatshini wokuGulisha, uMatshini we-Mirror we-8K, uSika ukuya kumgca wobude,

Umatshini wokuSila njl.njl.

* Oomatshini banokwenziwa.